Ovens - what type should I be using?

The oven is the heart of the bakery. It was once the heart of the home kitchen too, but perhaps it has been replaced by the cooktop now. Nonetheless, through my work teaching and consulting about everything baking, the subject of ovens comes up constantly. In this article, I’m going to attempt to break down the various pros and cons of most types of ovens. It’s a big topic, so I won’t be getting into too much specific detail, but if people are interested in an analysis of baking ovens in the future, I’ll be happy to do a separate article on this.

Ovens come in all shapes and sizes. The fuel which powers your oven will be the major cost over the life of the oven, and it is also the thing which gives an oven its basic cooking characteristics. So generally, we categorise ovens by what fuel they use. But there is a lot more to consider, and this article will explore different types of oven, not based on their fuel source, but on how they will be used.

An oven is just a hot box for baking in, right? Well, no. Heat behaves differently depending on how it is obtained, and how it is used by the oven to cook food. And the infrastructure behind getting the energy to heat your oven is equally important, though many home bakers really don’t think about this when choosing their oven. We will cover both aspects in this article.

What will your oven be used for?

If it’s designed for home use - in other words to do a variety of things, like roast, bake and warm food of all types. it’s likely that the heat will be distributed through the oven via the use of fans or venting - we call this a ‘convection oven’.

Convective heat is, effectively, indirect heat. The energy flows into a heat source (radiant heat) and is converted into heat which travels through air to cook food. As such, this type of heat is quick to heat space, but is also fickle, in that it disappears as soon as you open the oven door, and can fluctuate quite a lot during the baking process..

Note: I’ve written another article about heat dynamics here which explains what ‘convective’ heat is, as well as ‘conductive’ heat, and ‘radiant’ heat. Have a look at it for more detail

A home oven is designed to be a multi purpose tool - it’s pretty good for many different things. However, it isn’t necessarily very good at just one thing. If, for example, an oven is to be primarily used to bake pizza, convective heat is less important than radiant and conductive heat. This is because convective heat is inefficient for heating things. It hits the surface of the food and bounces off, continuously, leaving a little heat behind each time, until the food is cooked.

If you are cooking a pizza, you need very strong and efficient heat - heat which will travel through this flat object very rapidly. To do this, the heat has to be direct - which means it will be conductive or radiant (or both) to cook the pizza. Direct heat penetrates dough more efficiently than indirect (convective) heat.

An oven which has a flame or heat source of some kind inside the baking chamber can be said to be strong on radiant heat. So an old fashioned gas oven has stronger radiant heat than an electric convection oven, as most gas ovens have a flame which heats the baking chamber directly.

There are exceptions, of course - you can get gas convection ovens too, which have a flame burner hooked up to a venting system to heat the oven indirectly (convectively). You can also get old fashioned electric ovens which have an element inside the baking chamber, which effectively makes it a radiant heat type of oven. But the point here is that an oven designed to cook pizza will need to have strong direct heat.

A pizza is generally cooked on a pizza stone or on a masonry base (hearth), which provides ‘conductive’ heat. Conductive heat is about as direct as heat can get. Thus, conductive heat is the most efficient to bring heat into something quickly, as it doesn’t need to travel through air to do its thing. A pizza oven, with the fire inside the chamber, and with a lot of solid material around it, is a device where thermal mass is leveraged to become both conductive and radiant heat. The bricks get super hot, both over and under the pizza. It is important for the bricks under the pizza to be able to reach a very high temperature, and this is why traditional pizza ovens are dome shaped, as this focuses the heat on the central part of the floor of the oven, like a magnifying glass can be used to burn things. The dome shape also helps to amplify the heat in the top of the oven - so it’s radiant heat is strong too.

It’s worth mentioning here that this focus of heat can only maintain high temperatures for a short time, as the pizza itself absorbs this heat very quickly so it needs to be replenished regularly for continuous baking.

Bread requires a completely different type of heat. The dough is not generally flat (unless you are baking flatbreads, of course, but that’s a whole other subject), for a start. Bread is thicker, taller and moves around under heat much more than a pizza as the bread rises. So you need steady heat with a little moisture, diffused evenly throughout the baking chamber. This heat needs to last much longer than the heat to cook a pizza, so indirect heat is a good way to go here. However, bread also likes direct heat to help it to rise better, and to cook all the way through.

You will have had the experience of cooking some bread in a convective oven - it looks cooked, the crust is the right colour, so you take it out, slice it open and discover the inside isn’t cooked - just the outside. This is because convective heat cooks from the outside in. This is why convective heat (indirect heat) alone is not the best kind of heat for baking bread.

Bread really benefits from conductive heat, just like pizza. This type of heat will cook the bread all the way through at about the same speed as the convective heat cooks it on the outside. However, while pizza likes a short sharp hit of heat; bread likes slow and steady heat, so temperatures are lower and steadier. In general, if an oven is primarily to be used to bake bread, it should have good thermal mass.

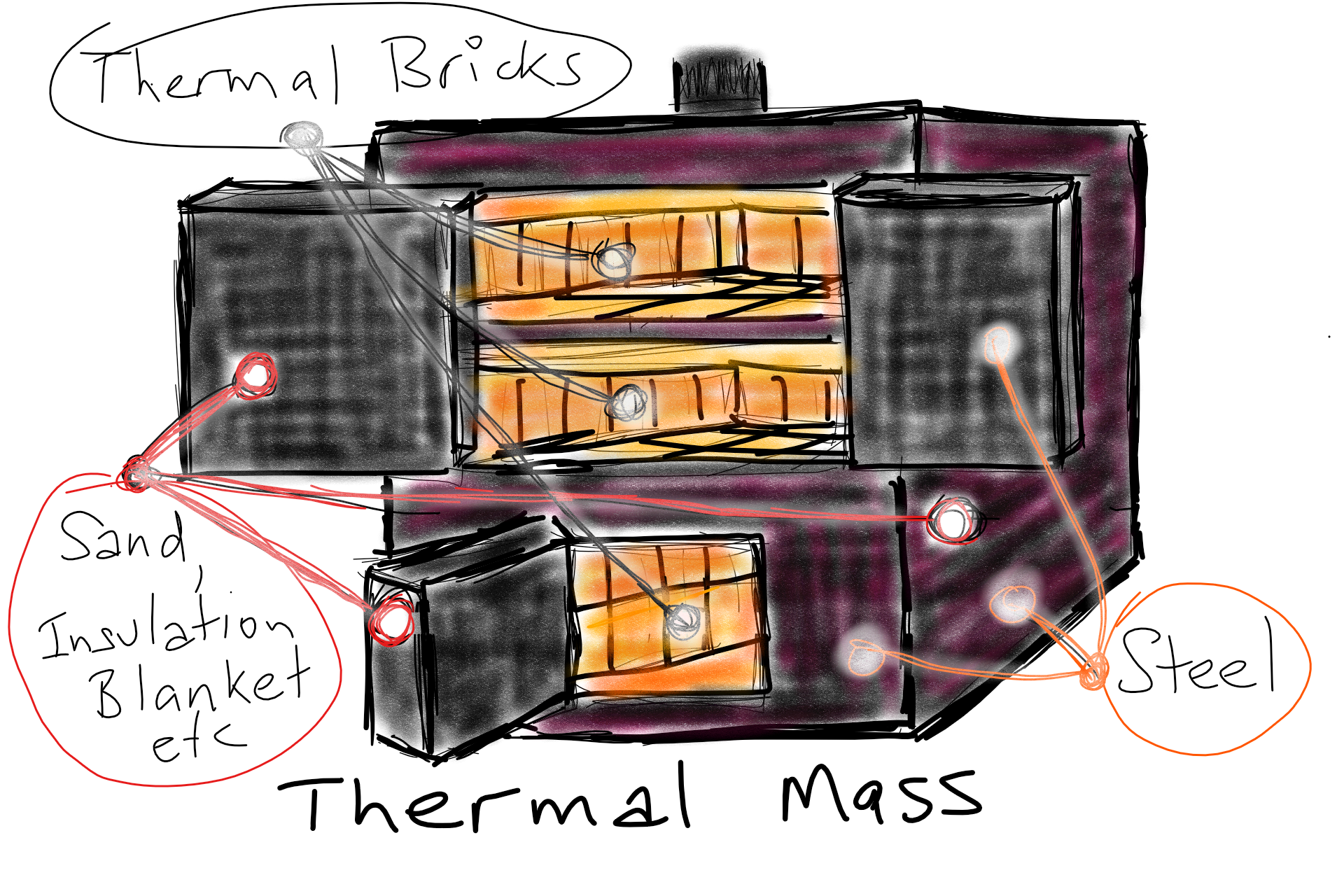

Thermal mass in ovens

Thermal mass is a term which comes up a lot in discussions about ovens. The best bread ovens have lots of thermal mass. This is for both conductive heat (the ‘sole’ or ‘hearth’ of the oven) and for radiant heat. Thermal mass soaks up heat like a sponge, until it begins to give it off. Once it is fully soaked in heat it becomes a radiant heat source. An oven which has a lot of thermal mass is said to be strong on radiant heat. Generally, a wood fired oven is made out of mostly brick, so there is a lot of thermal mass to cook with, and thus stronger radiant heat. Commercial deck ovens in bakeries also have more thermal mass than regular ovens for this reason too.

By the way, thermal mass actually helps with all types of cooking. If you are roasting or searing meat or vegetables, strong radiant heat makes everything more succulent.

In my sourdough workshops, I spend quite a bit of time showing ways of adding thermal mass to your home oven to improve your bread and baking. If this interests you, I run these workshops every month or so from my micro bakery. We cover all aspects of sourdough at these workshops as well, and we use my wood fired oven to bake bread and pizza.

Thermal mass is useful in all kinds of baking, but it does have a down side - it takes quite a while to heat an oven with a lot of heavy thermal mass. The trick to using an oven with a lot of thermal mass is to use it often, thereby keeping some heat in the bricks all the time, or, if you don’t use it every day, to use it for longer periods, to get the most use out of the heat you have created. For example, when I was baking out of the Bush Bakery Mk1 in Ellalong, my 3 tonne oven (Luna) took about 5 hours to get hot, so I would bake at least a few hundred loaves each time I fired the oven up, and I would use it on multiple days if there was enough demand.

Quick guide to oven types

Okay, so we have covered the theory behind ovens a little now. How does this relate to helping me to decide which oven to buy or use? Here’s a quick guide to the ovens themselves. I’ll go into the infrastructure required for each, and the differences between heat sources.

Convection ovens - gas or electric: Good all purpose ovens, quick to heat and cool. Can be used for roasting, baking, basting etc. Pastries, cakes and tinned breads can all be baked very well in a convection oven. Suitable for artisan bread, though not so much if you will be baking bread in them more often than other things. Then you would need to look at either an oven with more thermal mass, or adding some thermal mass to the oven to make it steadier. These ovens are not really suitable for pizza, generally, as they cannot get hot enough or provide enough direct heat.

For convection ovens, you will need enough energy coming in. If they are gas ovens, the right type of gas will need to be connected to where you are baking - bottled gas is LPG, while online gas is called ‘natural’ gas. The ovens will be jetted differently for each type, and it is sometimes possible to change the jetting in the oven to suit either type.

Home electric convection ovens run on single phase power, so they can just be wired in. For a commercial application, most (electric) bakers ovens require 3 phase power.

Note: There are a few specialist ovens now available for micro bakeries which can be run on single phase power, which I’ll be writing about in another article down the track. Most micro bakeries don’t have cheap access to 3 phase power, so there has been a market for these single phase ovens for many years, and it is only now that we have some choices.

Direct fired ovens - gas, electric or wood fired. Any oven which has the heat source inside the baking chamber is called a direct fired oven, so this includes old fashioned gas and electric ovens where the burner or element is actually in the oven. This also includes most deck ovens, as the elements or burners are inside the chamber. Obviously a pizza oven is a direct fired oven too. In the trade, a wood fired direct oven is also known as a ‘black’ oven, meaning the smoke circulates in the chamber.

Direct fired ovens can be used for anything, depending on what it has been engineered to do. They are generally the best ovens for bread and pizza, as the radiant heat is stronger. However, most specialized pizza ovens do not bake bread well, as they are not designed for the type of heat bread requires. To this end, there are wood fired direct ovens which ARE designed to bake bread - for example an Alan Scott style of oven (shallow dome) or the traditional Scotch oven, which was once the standard oven in any bakery around Australia (going back half a century).

There are still direct gas ovens made, both for commercial and for domestic use. There is currently a push to stop using them for various reasons, but despite this, direct gas fired ovens are very useful bakery and home ovens, with strong fast heat suitable for all types of baking. I question the motives of anyone coming down hard on gas or wood fired ovens - if they are properly installed and run correctly, these ovens are very efficient, very clean, and bake great bread. However, in recent years (in Australia) gas prices have increased dramatically, so they are no longer a cheaper alternative to run.

Indirect Fired ovens - can be gas, electric or wood fired. These ovens utilise a separate firing chamber which is positioned under or beside the baking chamber. The difference between an indirect oven and a convection oven is that an indirect oven relies on the transfer of heat through thermal mass, rather than through air vents. The firebox heats the thermal mass, and the thermal mass cooks the bread.

Indirect ovens are best for bread, as their heat is steadier and more even. They are almost always purely for commercial use, as an indirect oven will require a larger footprint in most cases than a convection oven. It is widely thought that indirect ovens take longer to heat than direct and convection ovens, though I’ve personally designed a number of indirect ovens which heat up just as quickly as other types. There are also a number of indirect fired ovens available commercially which use different types of thermal mass so they heat up quickly as well.

In wood fired versions, they are known as ‘white’ ovens, as the smoke stays out of the baking chamber.

This type of oven can be found in large artisan bakeries, whether powered by electricity, wood pellets or gas, because they have a lot of thermal mass and can be run for long periods at a constant temperature very efficiently.

While masonry is a common type of thermal mass, some of these ovens have oil circulating around the chambers instead. Others utilise sealed hot air ducts surrounding the baking chamber, which has the same effect as masonry but is much lighter.

Indirect fired ovens have also been referred to as ‘setter’ ovens, as the dough can be ‘set’ directly on the sole or hearth of the oven, due to the evenness of the heat in the baking chamber.

The infrastructure to heat these ovens is a bit more involved.

I don’t know of any commercial indirect ovens which can be powered by single phase electricity - they all require 3 phase, so you need to have a budget to get 3 phase put on, or already have it (let me know in the comments if there are any single phase versions).

If they are gas fired, the same issues with LPG or natural gas need to be addressed. And if they are wood fired, like with all wood fired ovens, you need affordable access to a reliable supply of wood, and the ability to store it so that it stays relatively dry. Lately, many wood fired direct ovens are powered by wood pellets, which are very efficient and convenient to use, but again, you need the correct infrastructure to run an oven with wood pellets.

So that’s about it for this article. If you are considering starting a micro bakery, or are already running one but need some support to scale up, our 4 day Masterbaker Workshop could be extremely helpful. Day 1 of this workshop goes into some detail of a microbakery setup, while the next 3 days students work a production run in an actual micro bakery.